Technology is constantly evolving, and one of the most exciting areas of innovation is in mobile display manufacturing. With smartphones becoming an indispensable part of our daily lives, the demand for high-quality displays has never been higher. In this blog post, we will explore the latest trends in mobile display manufacturing and how they are shaping the future of technology.

One of the key trends in mobile display manufacturing is the shift towards OLED (Organic Light Emitting Diode) technology. OLED displays offer several advantages over traditional LCD displays, including better color reproduction, higher contrast ratios, and faster response times. This has led to an increasing number of smartphone manufacturers adopting OLED displays in their devices. In fact, leading smartphone manufacturers such as Apple and Samsung have already incorporated OLED displays in their flagship devices.

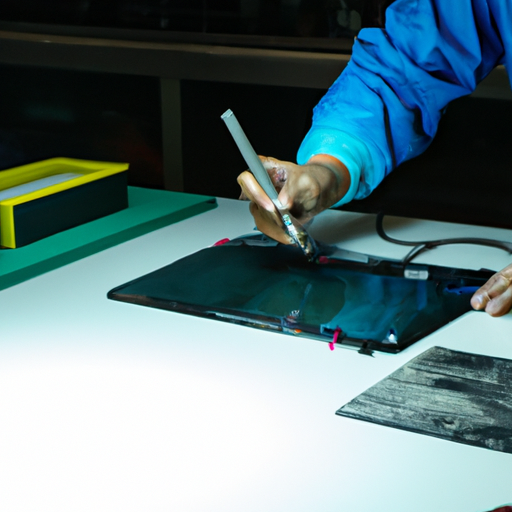

The process of manufacturing OLED displays is complex and requires precision and expertise. The first step in manufacturing an OLED display is to deposit organic materials onto a substrate using a process called vapor deposition. This is followed by the deposition of metal electrodes and a transparent conductive layer. Finally, the display is sealed with a protective layer to prevent damage.

Another trend in mobile display manufacturing is the use of flexible and foldable displays. With the advent of smartphones with foldable screens such as the Samsung Galaxy Fold and the Huawei Mate X, manufacturers are exploring new ways to create displays that can be bent and folded without compromising on image quality. This has led to the development of flexible OLED displays that can be curved or folded without breaking.

The process of manufacturing flexible OLED displays involves using a plastic substrate instead of glass, which allows the display to bend and flex. This opens up new possibilities for smartphone design, as manufacturers can create devices with unique form factors that were previously not possible.

In addition to OLED technology and flexible displays, another trend in mobile display manufacturing is the use of advanced manufacturing techniques such as laser cutting and nanoimprint lithography. These techniques allow manufacturers to create displays with higher pixel densities and thinner bezels, resulting in a more immersive viewing experience for users.

Laser cutting is used to create precise cuts in the display panel, allowing manufacturers to create bezel-less designs that maximize the screen-to-body ratio. Nanoimprint lithography, on the other hand, is used to create patterns on the display panel at the nanometer scale, resulting in displays with higher resolution and pixel density.

Overall, the latest trends in mobile display manufacturing are focused on creating displays that offer superior image quality, flexibility, and immersive viewing experiences. As smartphone manufacturers continue to push the boundaries of technology, we can expect to see even more innovative display technologies in the near future. Whether it’s OLED displays, flexible screens, or advanced manufacturing techniques, the future of mobile displays is bright and full of possibilities.